827

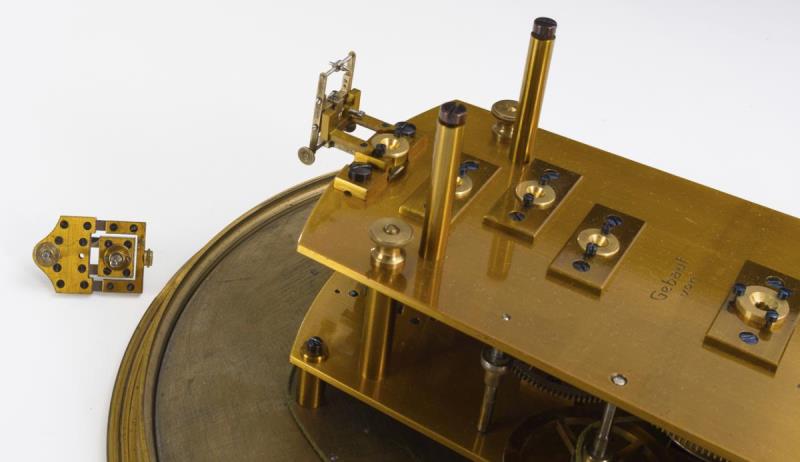

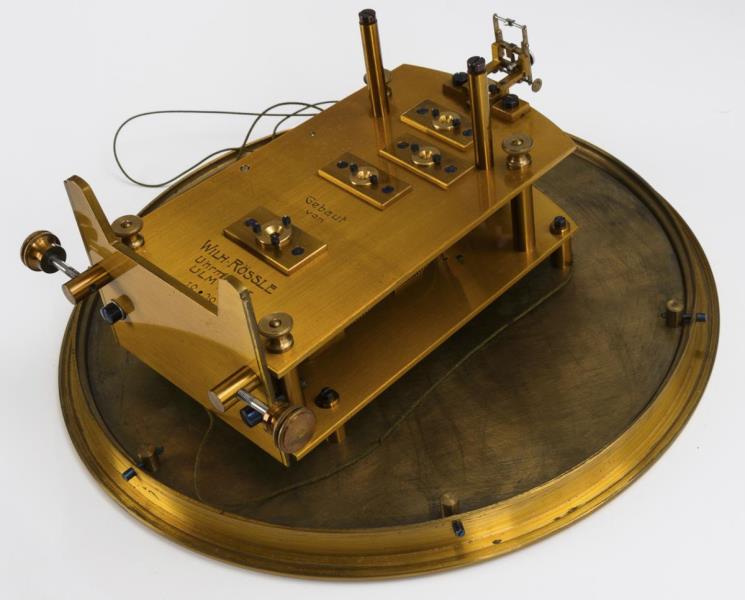

Seconds pendulum clock "System Prof. Strasser Glashütte i.S." with nickel steel compensation pendulum No. 969 by Sigmund Riefler.

made in 1909 by the Ulm clockmaker Wilhelm Rössle (1866-1933).

Ca. 159 x 50.5 x 24 cm.

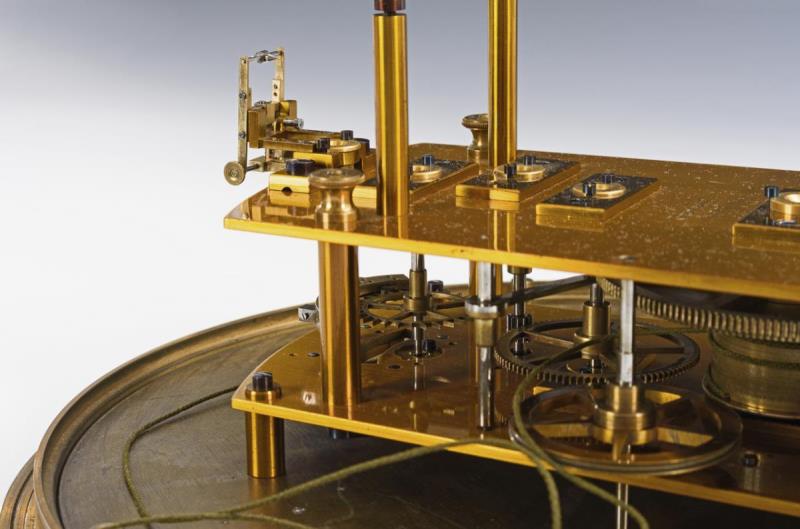

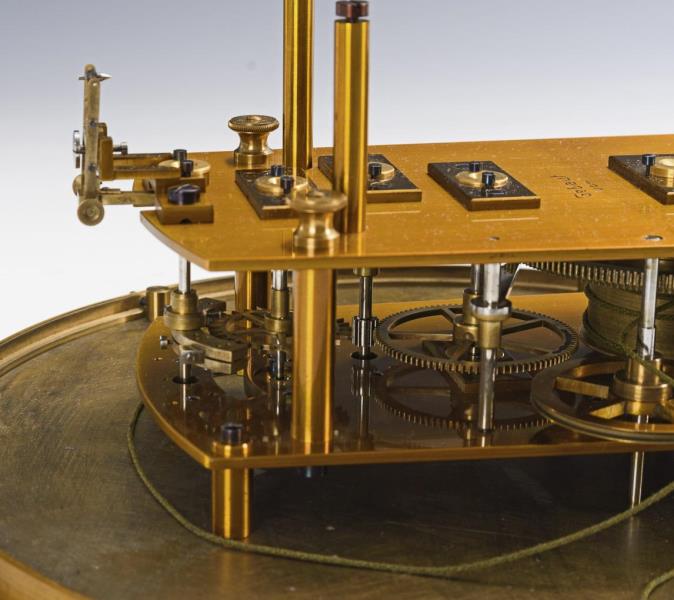

Precision pendulum clock with temperature compensated Riefler pendulum no. 969 DRP no. 100870 (invar rod Ø 10 mm), 8-day duration. Signed brass movement with Strasser escapement and lateral weight guide, massive movement pillars, lever with jewel pallets, screwed chatons, jewels up to the minute wheel. Signed silvered regulator dial with Arabic numerals for circulating minute track and eccentric seconds at 12, Roman numerals for small 12-hour indication at 6, blued hands, winding square in hour tube, brass bezel. Front faceted walnut case with side windows, temperature display, sliding carriage with oscillating scale. Accessories: 1 invar pendulum, 1 brass weight with old ropes, 3 cranks, 3 allowance weights for fine adjustment, 1 case key. The clock has a separate back, which is firmly attached to a wall, so that the case can not influence the movement of the clock. Only then the movement and pendulum block are mounted on the wall plate. The glazed clock case with dust-proof closed door is put on at the end. The clock is not shippable and requires a professional assembly.

The clock offered here and Wilhelm Rössle made with Glashütte components and signed combines the highest quality clock components for the time for improved accuracy and for the perfection of precision pendulum clocks - the free escapement of Ludwig Strasser and the temperature-compensated nickel-steel pendulum of Sigmund Riefler. Since it was not uncommon for watch factories and watchmakers to buy in or supply individual components, it was possible to manufacture and further develop precision clocks with the best precision engineering. Wilhelm Rössle (1866-1933) was an Ulm watchmaker and master watchmaker (1930-32) with a watch and goldware store at Platzgasse 5. After his death, the Ulm Museum acquired his extensive collection of grandfather, wall, saddle and travel clocks as well as pocket watches, dials and pocket watch movements from the 16th to 19th centuries, which provides a comprehensive overview of the history of watch development. Ludwig Strasser (1853-1917) was one of the most important Glashütte watchmakers. From 1885, he was director of the German Watchmaking School in Glashütte, and as early as 1875, together with Gustav Rhode, he founded the Mechanical Workshops Strasser & Rhode, which produced precision pendulum clocks, measuring instruments and marine chronometers and supplied astrophysical observatories, observatories and naval observatories, as well as the Imperial Marines. Around 1897, he developed the free spring escapement for seconds pendulum clocks, which was later named after him and patented, the so-called "Strasser escapement", which serves to drive precision clocks as uniformly as possible. It has an armature with double claws and a simple escapement wheel. The pendulum spring provides the driving force for the pendulum, thereby providing the necessary energy supply to keep the pendulum swinging. The pendulum used in this clock is an invar pendulum designed by Sigmund Riefler (1847-1912), one of the most important engineers, physicists and inventors in the field of precision clock manufacturing. The son and successor of the renowned watchmaker and precision mechanic Clemens Riefler (1820-1876), he devoted himself to the development of new measuring and drawing instruments as well as to the improvement of timing devices and precision clocks. In close cooperation with scientific institutes, observatories and time services, Riefler strove to improve the clock escapement and the pendulum, since the uniformity of the rate depended essentially on both. With his "free spring escapement," patented in 1889, and his novel mercury-compensating pendulum, developed in 1891, he was finally able to decisively improve the rate accuracy of precision pendulum clocks. After Charles Édouard Guillaume discovered a special nickel-iron alloy in 1896, Riefler was able to replace the mercury compensation pendulum and greatly simplify the method of temperature compensation. However, since the new nickel-iron alloy pendulum rods showed significantly adverse thermal effects on rate behavior due to residual molecular stresses, Riefler developed an elaborate reworking process in which the coefficient of expansion of each rod was determined and the rods were reworked in a specially constructed annealing furnace for 20 days. Due to the excellent properties and long-term stability of the pendulum rods associated with this process, Riefler accomplished an engineering feat. From 1907, this nickel-steel alloy became known as Invar, derived from "invariable" (unchangeable). A total of 4104 Invar pendulums were manufactured, but Riefler himself had only 635 of them built into Riefler watches. The majority was acquired by other companies, including Siemens, Bürk & Söhne, Junghans, Lenzkirch, Neher and many others. Ludwig Strasser acquired 82 Riefler pendulums for Strasser & Rhode to install in his best astronomical clocks.

Literature : Die Uhrmacher-Woche, No. 32, 1934, p. 430 and Die Uhrmacher-Woche, No. 42, 1934, p. 555. Huber, Bernhard: Ingenieur der Präzision, Pendeluhren von Sigmund Riefler, pp. 7-43, in: https://uhren-muser.de:8080/chronohype/ChronoHype-Magazin_Nr_4.pdf. https://www.glashuetteuhren.de/die-uhrenfabriken/strasser-rohde-von-1875-1917/.

Provenance : From a private household in Thuringia.

Shipping not available.

Call time 25 | Oct 2023 | expected 18:59 (CET)

Limit 20000 €

• LIVE Auction starts in -844 days

• Calling time: 25. | Oct 2023 | approximately 18:59 uhr

• Calling time: 25. | Oct 2023 | approximately 18:59 uhr

Lot is returned to owner.

Log in